20 Jan 22:

In our search to find small boat plans that would be easy to build and fit in the back of a pickup, we came across Joel White's Nutshell Pram, the 7' 7" model. It would be a good boat for many purposes, as a tender, sail trainer, fun rowboat for kids. The plans and builder's guide was ordered late in 2020 from the WoodenBoat Store, then the project was postponed by our punt build and a homeport change.

We're reviewing the plans, considering a build.

27 Jan 22:

Here's a little information of the plywood we chose for the Nutshell Pram build, marine grade okoume.

Video Link: https://youtu.be/Wmnbhd8dnlU

27 Jan 22:

(Builder Note:) It will save time to make the laminated frame and forekeel first, that way they can be drying while the molds are cut out and the ladder frame assembled.) We cut out the building molds for the Nutshell Pram today, they are temporary pieces that help define the shape of the boat while it is in the first stage of construction. The plans call for 1/2 or 3/4 inch plywood, or they can be put together from pieces of solid wood.

27 Jan 22:

There are 8 sheets of plans and patterns for EXCUSE ME from WoodenBoat.

28 Jan 22:

The plans call for a forekeel and a midships frame to be shaped out of thin strips of wood, laminated together with adhesive. In order to do that we first needed to make a bending jig to hold the wood and adhesive to shape while the adhesive dries. We traced the pattern onto some scrap 1/2 inch thick plywood with a pen and carbon paper.

29 Jan 22:

We added clamping blocks to the bending jig. Spacing is arbitrary, with enough blocks around the curves to ensure the proper bend.

30 Jan 22:

We worked on the forekeel today for EXCUSE ME, but first a couple of close up photos of the midships frame clamped and drying.

Here's a few tips on lamination:

Video link: https://youtu.be/7OZ_1mz2qFA

The jig was then taken inside the house to dry in a climate controlled, 72F space.

30 Jan 22:

The pram has a bow and stern transom, we traced the patterns onto a 3/4 inch thick sheet of marine grade okoume plywood. The plans call for 1/2 a sheet of 4x8 plywood, hard to find, and we can tell you that there is a LOT of plywood left over. Maybe it will be made into a daggerboard or rudder.

Bottom centerline. Also there is extra wood left for the bevel that is to come.

Current state of the Mid Atlantic Carriage House.

04 Feb 22:

Time to plane down the excess epoxy and wood strips for the forekeel and frame. We ran them through our DeWALT planer, decreasing the cut 1/32nd of an inch each pass, and flipping the workpiece before each pass. Since the curved frame was not too wide, we were able to guide it through with no issues.

06 Feb 22:

Today we cut the ladder frame sides to length and screwed in the cross supports.

...and transferred the angle over to the ladder frame stern transom support. You may choose to level the ladder frame fore/aft and side to side at this point, but we are going to level right before we install support legs to the molds and frames, then check level again.

07 Feb 22:

Time to make sure the ladder frame is level, so that the transom and mid frame will be level.

08 Feb 22:

We worked on the bottom plank bevels today, necessary so the lower edge of the garboard plank has more surface on the bottom plank to adhere to. First we made some battens and attached them to the jig on the face of the molds, frames and transoms where the inner face of the garboard plank will lay.

09 Feb 22:

Traced out lines for the planks from the plans.

Here's a few tips on cutting the planks and a discussion of what's next for the Pram. The first 4:48 is shaky due to the saw.

Video Link: https://youtu.be/WfDSzZE4Ndg

11 Feb 22:

Placed the first garboard plank on the building jig to check the shape. Used one of our lap clamps to hold the plank in place at the mid frame while we checked the fit.

13 Feb 22:

Yak shaving is when we start off to do one thing and end up doing 2 or more other things, while avoiding the original task. Today we planned to attach the middle planks to the Nutshell Pram, but when I walked into the Carriage House it was almost 80F inside. Partly because it was 72F outside and also because the Carriage House has a charcoal colored metal roof. So the first order of the day was to open the Carriage House windows for the first time for some cross ventilation.

It was so nice outside that we decided to liberate the deck furniture cushions from the loft and put them to use, but first I needed to replace 3 slats on the love seat.

14 Feb 22:

Let's see, what to do today? Planking? That's it. A few notes follow as we continue planking our Nutshell Pram EXCUSE ME. One note is that it's a goo idea to mark which edge of the plank gets epoxy. We had a work slowdown today when i gooped the wrong edge, it's easy to get confused as the plank gets taken off from dry fitting and hauled over to a work table. So a little pencil mark helps, as do a few scribbles as to where the transom surface will get epoxy.

A video: https://youtu.be/ULc7sXbjqCk

Another video: https://youtu.be/VmZuQ0590eY

We hope you remembered to cover the molds, so they don't stick to the hull :)

A tip from Charlie, this screw acts as a third hand to help hold the plank during dry fit and again during final attachment of the plank.

15 Feb 22:

Cold outside today, in the 40s, so we set up a little space heater under the hull for a few hours to help dry the epoxy. The heat rising raised the hull temp enough to keep the cure going on the epoxy.

16 Feb 22:

EXCUSE ME came off the molds today! Skipper and crew helped with the turnover.

24 Feb 22:

Contemplating quarter knees, there are three bevels to contend with, the plank/transom bevel, the transom bevel and the side plank bevel. One tip was to make cardboard templates to get the plank/transom bevel.

08 Apr 22:

Finished pondering the quarter knees and made the first cuts from mahogany. We used a cardboard template for the side plank to bow angle.

Now we need to find the bevel for the side, and then the bevel for the bow. For those wondering, the quarter knees help tie the side planks to the bow and stern transoms.

15 Apr 22:

Time to shape the quarter knees for the Nutshell Pram, the knees reinforce the connection of the gunwale to the transom. We started by finding the angle between the transom and the gunwale with our pocket bevel, and cut out that angle on a piece of 1 inch thick (4/4) mahogany. Next we drew the curves of the inner knee shape, the part that faces the inside of the boat. This shape was constrained in one direction by the width of the board that we had, about 7 inches wide, but the side that ran along the gunwale could be as long as we wanted. We referenced the plans, drew out traditional knee curves in the inner face and cut the inner knee shape.

In this photo we have jumped ahead to the finished knee for the port side, bow transom knee. The bevels for the transom and gunwale have been cut so that the knee fits with a slight rise going up the face of the transom. Another option would be to run the knee straight across, parallel to the waterline, but we liked this look better.

25 Apr 22:

Bevel Tips Part 1:

25 Apr 22:

Plans call for a 5/8th inch wide by 1 inch tall, one piece gunwale, attached to the outside of the sheer plank. We decided to rip 3/8th inch strips and have both an outer and inner gunwale, to create a handhold. Ripped the pieces on a De WALT portable table saw.

Video: Nutshell Pram EXCUSE ME 25 Apr 22 Gunwales

30 Apr 22:

We started looking at plans for the daggerboard trunk and daggerboard, and noticed that the plans called for the daggerboard to be made out of 2 layers of 1/4 inch plywood. My brain remembered that we had daggerboards from early Alcort Sunfish that were close in size to the Pram daggerboard, but they are 3/4 inches thick. So I checked with Maynard, one of the design team for the Pram, to see if an ich here or there would matter, and he said it would be fine.

We used the new daggerboard to make sure we made the trunk wide enough front to back, the Sunfish daggerboard is 9 inches vs the design 8 inches, The Sunfish daggerboard is also 31 inches vs 28 a little extra daggerboard will be fine and it still will fit behind the aft seat when not in use.

03 May 22:

We ordered the line for EXCUSE ME, we selected New England Rope Vintage 3 Strand, purchased from R&W Rope. We usually order extra for sail ties and longer bow line.

07 May 22:

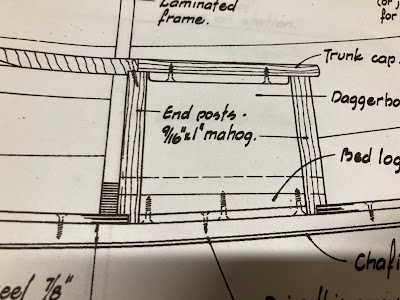

Time to assemble the daggerboard trunk for EXCUSE ME. We loose fit the pieces and drilled countersunk pilot holes for the silicon bronze wood screws.

28 May 22:

EXCUSE ME got her new line today, some 3/8th inch New England Rope Vintage 3 strand. It will be used for the bow line, halyard, sheet and bridle.

22 Jun 22:

We picked up some spruce today to butcher into spars for EXCUSE ME's new sail.

Mast:

22 Jun 22:

Almost finished, it needs reefing lines, spars and a trip to the beach to check out the shape in a sea breeze.

23 Jun 22:

We cut up some lumberyard 2x4 spruce for spars today, we picked the best boards we could find with as few knots as possible along the edges. We cut the yard to length first with a small circular saw.

There is so little taper that we worked the corners off with a spokeshave, then mostly rounded the yard. On a larger piece with more taper, we could use a batten for draw the taper on the sides and shave the excess off with a bandsaw, the shave the adjoining sides, use a spar gauge to 8 side the spar, sand etc...but that would be some very fine cutting on this small of a spar. Old Timers might even leave the mast or boom square and just go sailing, what's a few ounces of weight between friends?

24 Jun 22:

So once the sail is made it's time to outfit it with a lot of string and bronze bling. The lug rig needs a halyard, sheet, reefing lines, ties for the peak, throat, tack and clew, lacing line for the yard, snap schles for the sheet and boom and some thimbles for the sheet.

Reef line...in case you need to reef 37 square feet...We used New England Rope Vintage 3 Strand, whipped the ends.

24 Jun 22:

The Nutshell Mast is 8' 5" long, and the widest diameter is just above the base where it flares to 2 3/8". The bulk of the mast is 2 1/8" though, so we decided to make the blank 2 1/8" and save on some carving. It should be plenty strong, as a comparison our Sunfish mast is 2 1/4" diameter and it carries 75 square feet of sail, twice that of the Pram. We just have to remember down the road to cut the mast thwart hole to 2 1/8".

We cut 2 pieces to length, then ripped them 2 1/8" on one side and 1 1/16" on the other. For adhesive we used TotalBoat THIXO Flex dispensed from their 2 component epoxy resin and hardener cartridge in a 25:1 High Thrust Caulk Gun. 2 beads of epoxy per face then we spread it with a paint stir stick to ensudre full coverage.

24 Jul 22:

We have to taper and 8 side the Nutshell Pram mast, thought this might be a good time to get an electric plane, we chose DeWALT because it matches our battery system. The first job for the plane was to remove excess epoxy from the mast blank, it made short work of it.

25 Jul 22:

Once we get the Nutshell Pram mast tapered we need to mark it so we can shape it to 8 sides. A spar gauge is the way to go, so I made one. But I had to overthink it for a while...

Marked and cut out a piece of spruce to make the guide. Used standard 7-10-7 dimensions, gleaned from Greg Rossel's book on boatbuilding.

30 Jul 22:

We had a question about how we attached the boom to the mast on the Nutshell Pram, we tied a vintage Sunfish sheet snap shackle to the sail lacings with 1/8th inch diameter New England Ropes Dacron cord. I suppose the cord could have also been run through the boom beehole. The attachment point on the mast is marked on the plans, where we screwed on a vintage Sunfish eyestrap.

13 Aug 22:

Work continued on EXCUSE ME's mast, we drew out the tapers on the base and cut them with our DeWalt cordless planer. The base of the mast is 1 3/8 inches in diameter, so we cound center and measured off either side of that, then used a straight edge to put down a Sharpie line.

14 Aug 22:

We made 2 of the 6 thwart cleats. First we found the bevel from the side plank to the bottom of the seat, and set that angle on the bandsaw.

17 Aug 22:

We're a week or two behind on the blog, so we'll jump forward to a few days ago and fill in blanks later. We are making patterns for the thwarts in the Nutshell Pram using a technique from the Wooden Boat School video series, so why not start with the hardest one, the middle thwart? It has a frame that we have to trim around, but, if we chowder it up, it is also the widest thwart, so we can try again with the butchered piece on the narrower bow or stern thwart.

First we needed to decide how wide fore and aft our seat will be. Plans call for 8 inches, but that was 40 years ago, so we are bumping it out to 9 1/2 inches. This will let us know how wide to make the pattern piece.

20 Aug 22:

We attached cleats towards the middle of the thwart, leaving clearance to work the thwart through the bandsaw. The pattern was marked on the thwart and both ends run through the bandsaw. We got lucky and got a nice fit from the first pass, did final fairing on the sides of the thwart with a random orbital sander.

21 Aug 22:

Took a measurement from the plans to figure out how far forward the aft thwart goes from the stern transom. From there we can determine thwart cleat placement. 3 inches is what I came up with.

23 Aug 22:

Installed forward thwart cleats with THIXO and bronze screws.

27 Aug 22:

I took out my calibrated Sharpie and marked the hole to cut for the daggerboard trunk. It is offset per design to keep the keel backbone strong, and so the keel will slide up onto a dock or boat or whatever without catching on a spot where a hunk is cut out for a trunk. Per design.

28 Aug 22:

Time to cut a hole in a perfectly good boat. We drilled a pilot hole for the jig saw, cut what we could from the inside then flipped the boat. Oops, first we shaped the ends of the trunk posts, they stick through the hull and will be cut flush with the bottom. Shinto rasp does the trick for this bit of butchery. Rounding the post keeps there from being hard corners, which can lead to stres points, cracks and leaks.

29 Aug 22:

Finished shapin the thwarts with a 45 degree chamfer along the lower edge, primarily to lighten the look of the thick teak. I could have run the teak through the planer and thinned them down, but Skipper wants the weight. Once the ends were trimmed we attached the last set of cleats to the forward thwart with silicon bronze screws, piloted and counterbored with a combination Fuller bit.

02 Sep 22:

While I was out flying the French Door Fairy dropped by and installed a hatch in the bow of the Boat Works. Skipper was complaining that her cabin was too hot, now there is a nice breeze, almost a wind tunnel, more light and a cargo portal to the foredeck (coming soon).

03 Sep 22:

Skipper picked out the colors for our Nutshell Pram and I sent in and order early this morning. I had a question about the primer we are using so I sent George, George IV in George Kirby Jr. Paint Company, a query. He responded immediately and I jokingly asked if he was in on the holiday weekend so he could make the paint for our pram. He said he was in every Saturday until Noon, and a little while later we got photos of George mixing EXCUSE ME's colors, which are Maynard Bray Off White, Fighting Lady Yellow and See Red. We also ordered some brushing liquid and a t-shirt.

From their website:

Our proud and rich family heritage began in 1846 along the historic waterfront in New Bedford, Massachusetts. Since then, Kirby Paint has had a front row seat as a key supplier to this historic industry. The company rose to prominence as one of the first manufacturers of copper bottom paint. At that time, a revolutionary product, made to eliminate the buildup of barnacles and other sea life that accumulates on the bottoms of boats, which is still a popular choice in our product line today.

George A. Kirby IV continues the family tradition of producing fine marine paints, primers, and other finishes. Our Kirby Signature Color line features an assortment of our timeless classics that you’ve come to know and trust. We also custom match an endless selection of classic, as well as modern, colors in a variety of finishes. We have always handcrafted all of our marine paint. This is what makes our paint different from the rest, premium ingredients and small, handmade batches. Thank you for choosing Kirby Paint! We invite you to visit our store at 163 Mount Vernon Street, New Bedford MA.

~George and Shari Kirby"

If you need some custom, quality marine paint, we'd highly recommend giving George a call. He answers the phone too!

04 Sep 22:

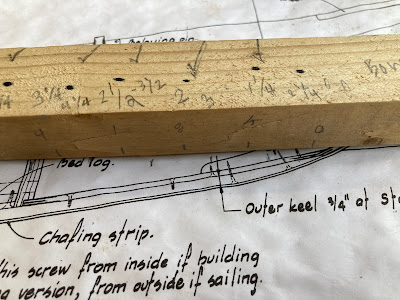

We cut and fit the keel, and per plan neither the top or bottom of the keel is straight from bow to stern. I wondered for a bit on how to mark our not-so-cheap piece of sapele mahogany so as to get an accurate cut line and optimize the amount of lumber left over. An expensive way to do it would be to cut a piece with plenty of excess along the cut lines, and scribe the top of that piece to the.....anyway, ask 7 boat builders how they do it and grab some coffee, you'll be there a while listening to 7 x infinity answers.

What I did was find a long stick and marked out 4 inch increments to scale to represent "stations." Once the marks were made we basically have a scale ruler, and I laid the measuring/marking stick on the plans. The stick was placed on the 2 high points of the keel drawing at the bow transom and stern transom. Station Zero we'll call it, was the mark that touched the bow edge of the keel drawing, and stations were numbered by inches then feet, so 0, 4, 8, 1, 4, 8, 2, 4, 8, 3... Confusing? Yes it was. To make things even better, the stick was numbered right to left.

Here's a photo of the stick.

That clears things up, right? A wider, flat stick would have been better, but this is what I had. And for this photo I took it later and the Station Zero tick mark, shown on the lower face of the stick to the far right, is not touching the uppermost bow end of the keel drawing. FYI, it was when I took the measurements. And there a lot of lines there, the top and bottom of the bottom plank lines, the tip of the keel, and the top and bottom lines of the chafing strip. The first bit of error can be introduced by using scaled plans vs full size patterns (which are not offered) but it's all part of the so much fun of messing about with boat building. Actually the first bit of error was to begin building a boat at all, if prescribe to Capn R. D. "Pete" Culler's philosophy (he was a serial boat designer and builder). Pete prefaces that belief with the wisdom that boat building was simply about correcting one mistake after another, with the first mistake being in beginning at all. "But oh what fun." He also advises that experience starts when you begin.

Oops, I wandered off there. The scale for these plas is 3" = 1'. Each mark on the stick represents 4 inches. It would have reduced my confusion if I had marked the stick using the Feet-Inches-Eighths convention. See how there are two four inch marks on the lower face of the stick? The one to the right is at zero feet, four inches, zero eighths, it's mark would be 0-4-0. Since we're reading measurements right to left, the four mark to the left is at 1-4-0, or one foot, four inches, zero eighths. These "Station" marks go out to almost 6 feet, and the problem with my lazy scheme is that I left a lot of fours and eights hanging in space with confusing context.

When WE, yes, you are in this with me now, no escaping...When WE get further to the left on Keel Stick v1.0, around 4 feet, numbers get confusing. Does that 4 mean 4 feet or is it 4 feet 4 inches? Here's where the Feet-Inches-Eighths numbering would come in handy.

Once we got the measurements on the stick we transferred those measurements to the expensive mahogany with a Sharpie dot, with the only measurement and Sharpie dot that we certain of being the Station Zero measurement and marking. Then we connect the dots using a batten to get a mostly fair curve, and make the first cut outside of the top-o-the-keel cut lines. At one point you have to cut of excessive lengths and widths of the lumber, leaving enough wiggle room for the scribing and fitting to come.

"The keel is attached!"

04 Sep 22:

Rolled some TotalBoat 2 Part Epoxy Surfacing Primer onto the Nutshell Pram. It went on quick and easy and smooth.

06 Sep 22:

Applied TotalFair to the hull, it's easy and fast to mix, and fun to apply. Sanding next.

07 Sep 22:

After a coat of primer revealed a few spots we missed, we applied some more TotalBoat TotalFair with a plastic spreader to the pram. Thin coats are best if a large divot is being filled, so that the compound dries properly.

Video: https://youtu.be/shiyFDsnQpQ

Skipper smelled the varnish and came out to do it the correct way, vs my mop technique. Her Dad Capn Jack was a varnish Master, she learned from cell memory and observation. She's been boat building since 1969, when she puttied all the screw holes on the family's Petrel sailboat with her little fingers, no gloves. Peeled off her fingerprints, she'd make a good bank robber to this day.

10 Sep 22:

The sailing version of the Nutshell has a daggerboard, and when in Tow Mode, a plug is recommended for the trunk, unless you like bailing swamped dinghies. Since we made the trunk a tiny bit bigger to repurpose a Sailfish daggerboard, we thought why not find another crusty Sailfish board and use the top part for the plug? So we put out a query to our Sunfish Guru Alan, to see if he had a board with suitable patina in his boat barn, and of course he did. We traded him a gudgeon backer plate and he sent us the top 1/3 of the board, so as to save on shipping costs. There were several emails back and forth with him checking to see if we sent the correct trunk depth measurements, 8 3/4 inches, as this small of trunk wouldn't register in his brain. He left an inch or so on the cut pieces and dropped the package off with USPS (Uncle Sam's Pony Service).

We cleaned it up with water and TILEX, then ran it through the dishwasher...

...okay I didn't really run it through the dishwasher, but if Skipper hadn't been around...

Later we put a sealer coat of TotalBoat Gleam Satin on the plug and the daggerboard.

Our tips on how to roll and tip paint onto a small boat. You'll have to peek around the shop rag at times and a brief period where the shot is out of focus, but the information is there. If you like, you could send us money to hire a videographer and editor, we accept paypal and patreon...We'd also like to read your suggestions on your favorite materials and methods.

Video: https://youtu.be/kW8g0kBLmRw

11 Sep 22:

We watched Geoff Kerr's Caledonia Yawl build series a few years back, incredibly informative. It was there or in another of his videos that he talked about a few different types of tape that he uses to get different border results when painting. But first a turtle, an Eastern Box turtle named Carolina came by to check out the our fancy new French door.

These different tapes have different temperature ranges and can be left on for different periods of time without lifting the coating beneath. If you're not sure which tape to use you can post a question below, or wander over to the 3M Tape Selection Guide.

Our video: https://youtu.be/vLXnNdn-sxs

Many thanks to Geoff for sharing his painting materials and methods with the metaverse!

Here's the best video we've found on the paint process, from bare wood to the finish coat. Well worth a membership to Off Center Harbor to take a look at this video and the 42 part series on building a glued plywood lapstrake boat, in this case a Caledonia Yawl.

12 SEP 22:

Rolled out the keel chafing strip

13 Sep 22:

We rolled the second coat of interior primer onto EXCUSE ME, but first, TETRIS! Our Alcort Catfish SMEDLEY moved onto the Wheel Deck, inching his way towards hull(s) repairs this Fall. As the weather cools we'll use the back patio to enjoy the sun, or the new space behind the Boat Works. We also moved the mower out of the Heuer Garage to make room for our little punt SCUPPERS. (L-R) 1965 ALCORT Catfish SMEDLEY, SCUPPERS, 2017 Penobscot 14 ST. JACQUES, 1965 ALCORT SUnfish WAVE, 1981 AMF Sunfish MADISON (in hoist), 1982 AMF Sunfish PHOENIX, 1960s Grumman 17 SCOUT and 2021 Carry On HUEY II. Maybe if I strapped beach rollers to HUEY II he would make a nice amphibious landing craft of floating dock...

14 Sep 22:

We rolled and tipped the first coat of Kirby Paint Fighting Lady Yellow and wow, it has a lot of fight! The photos don't do it justice, it dried to a beautiful low luster, to compliment the sating finish on the brightwork, or "satinwork" in our case.

We put the thwarts back in for glamor shots.

15 Sep 22:

Build a boat the drill holes in it. This one for the painter aka bow line. We used the heirloom ratchet brace and an auger bit to drill the hole.

16 Sep 22:

Today we glued the rudder cheeks to the rudder blade using TotalBoat THIXO Flex, a flexible thickened epoxy. Thickened epoxy fills joints better than straight epoxy, and the Flex is formulated for movement of materials used in the marine environment. Light clamp pressure was used, only enough to see a good seam with epoxy beginning to squeeze out. No squeeze out could mean not enough epoxy was applied, so keep plastic syringes handy to inject epoxy as needed. Too much clamp pressure can force most of the epoxy out of the joint, and there will be poor adhesion.

Video: https://youtu.be/rI1WMXfSXg8

17 Sep 22:

At this stage of a project we keep a punch list, a list of things left to do, and we try to prioritize the sequence of fun so we don't end up at the end needing to fair, sand, prime, sand, prime, sand, paint, sand, paint, sand, paint and wait for paint to dry on a boat part. I'm not sure when the first bit of fairing compound went onto the boat, but it's been a few weeks. On this build I'm glad we took care of spars, sail and daggerboard midway through, and that's what we recommended to someone recently, actually we suggested that they build the rudder and daggerboard first, then spars, while they waited for bigger parts to appear.

I broke our Punch List down into the Row, Tow, Scull, Sail design categories and decided we needed to work on the row items, one of which was to screw down the aft thwart. To do that I needed the rudder so I could check the stowage space needed behind the thwart. So we installed the traveler and then placed the rudder and daggerboard behind the aft thwart to check for fit. That sounds kind of like yak shaving doesn't it? We then fastened the thwart with Frearson head silicon bronze wood screws from Fairwinds Fasteners. We leave the screw heads visible so that the thwart can be removed as needed, especially down the road when it's time for a topcoat of varnish and inboard paint, hard to varnish the bottom of a thwart.

So she can Row and Tow now.

18 Sep 22:

A few tips on installing the rudder hardware for the Nutshell Pram. We used a dowel to find the spot for the lower pintle bracket, leveled with the top of the gerboard plank.

Up top we found center from side to side.

20 Sep 22:

Hauled EXCUSE ME to the James River for a Float Test and Rowing Sea Trials. She passed both with flying colors. Easy to row and she doesn't need much space to get around. As for towing, the dolly/trailer combo worked out great, a few simple tiedowns and she's ready to roll right down to the beach.

A full review on the Nutshell Pram is being prepared for WoodenBoat's digital publication Small Boats Magazine, and it should be published in the October issue. Once we see which Sea Trial photos they chose we can post more here.

22 Sep 22:

Took our Nutshell Pram EXCUSE ME out for sailing trials, she performed much better than I expected, very responsive and a lot of fun.

Video: https://youtu.be/qwGFwkbUxY0

Skipper Skippervised and took photos, still awaiting medical clearance for high speed sailing.

Sail Trial Notes Video: https://youtu.be/IHmCWQgh868

This trailer/dolly combo has been working out great, parking lot right to the beach.

03 Oct 22:

Our boat profile article in Small Boats Magazine is hot off of the digital press, we relate our experience with the tow, row, sail and scull attribute of this capable little pram.

04 May 23:

We tried a little experiment of leaving EXCUSE ME outside for a few months without a cover, under the roof of the Sunfish Shack, during pollen season(s). As we might have expected, she was coated with a fair amount of dust and pollens, and picked up a few leaves. So she got a bath as well.

No comments:

Post a Comment